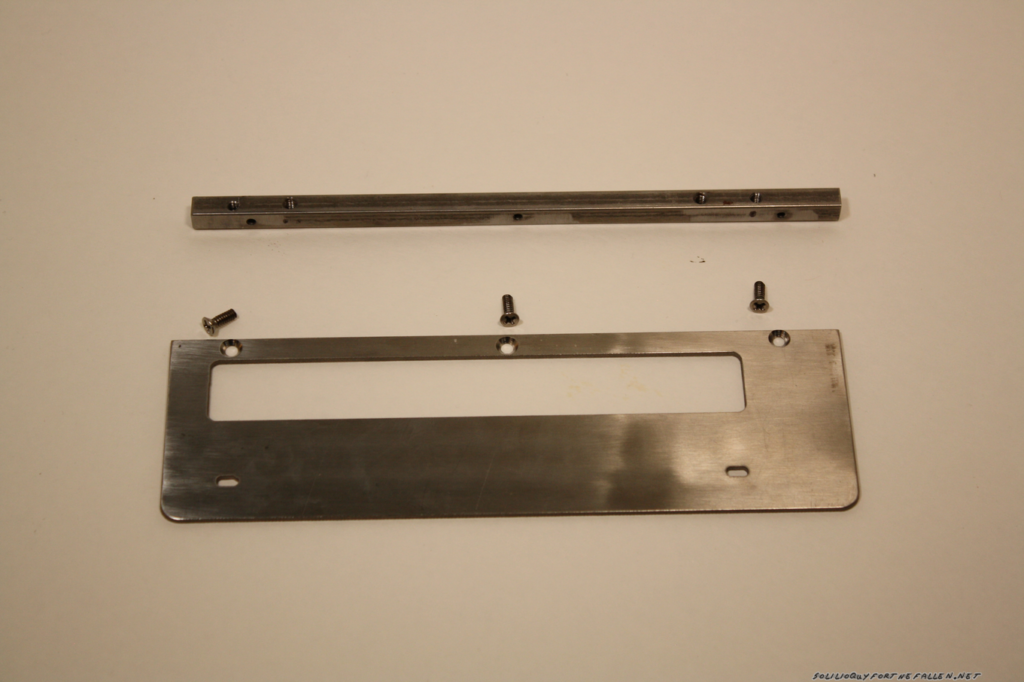

I wanted an inexpensive DMR radio for one of my vehicles so somehow I ended up with the Radioddity DB25-D. From what I saw it was about the best wattage for the least money once I shopped around and found it on a flash sale. I paired the radio with an inexpensive Retevis antenna from amazon.

At the moment, my one word review is ….. “don’t.” It’s a weird little radio with a particularly offensive “flaw” which I’ll discuss in a moment. Otherwise, the purpose of use was to monitor my DMR repeater and to test its range in the area. It seems as though it will suffice in that application.

So, “the issue.” When I first set up the DMR talkgroups, I couldn’t hear anything come back – it was like the radio was muted. But I could hear analog stations just fine. Then I reset the radio, it set the radio to “promiscuous” which is a DMR term for hearing all talk groups being broadcast by the repeater. Which made the issue more confusing.

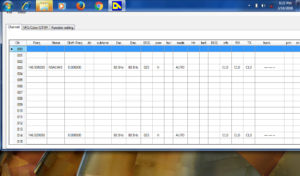

What I finally determined was that unless you set an Rx group, you will hear nothing. The solution is to create an Rx group for each talkgroup and then only add that talk group to the rx group. It’s stupid and madness and not what the CPS guide says. Update: This was changed in the 2023-0706 firmware this was changed to a more sensible behaviour.

Another item on the list of complaints is though this is Radioddity’s radio and I bought it from them … it came with outdated firmware.

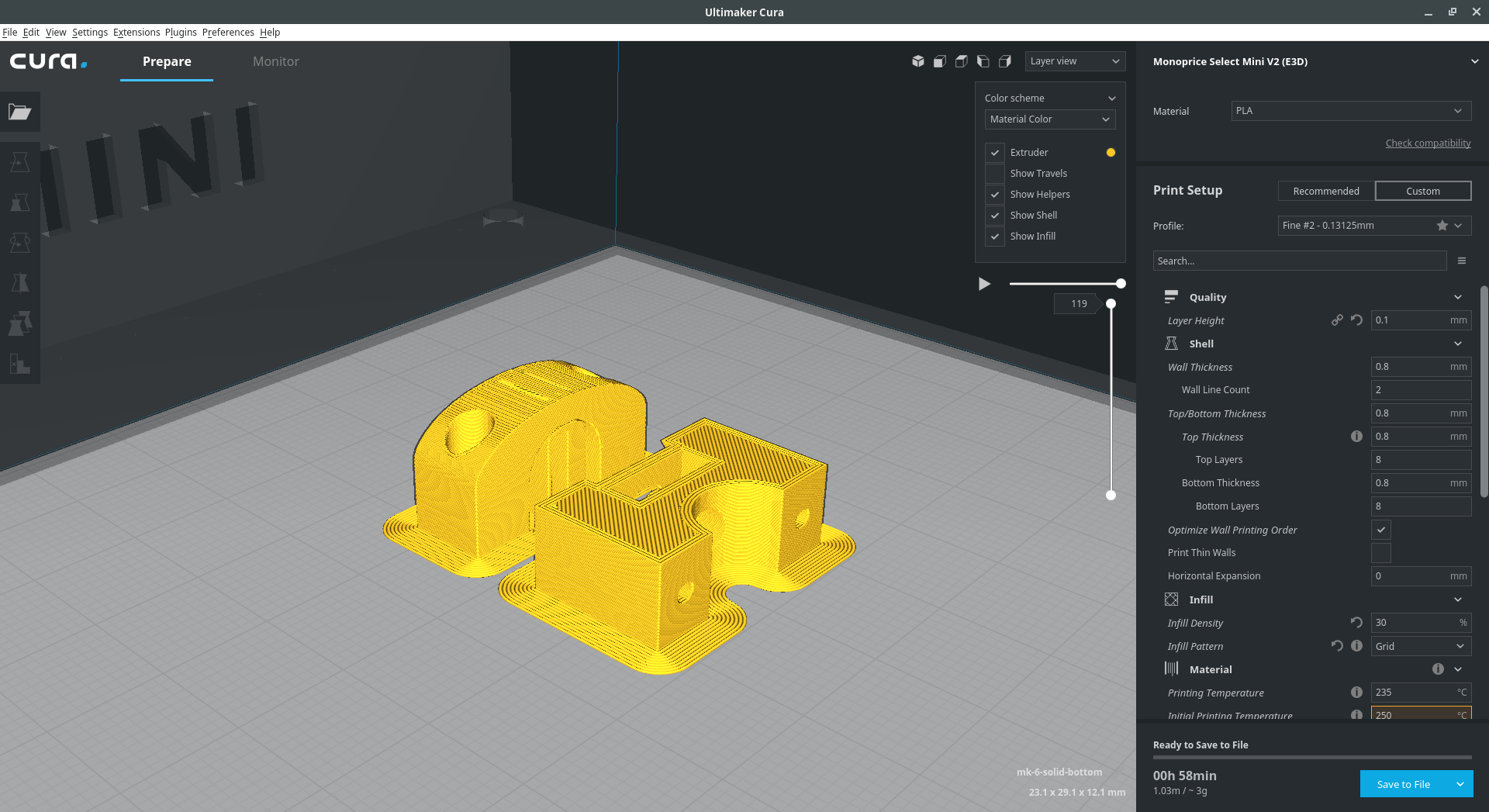

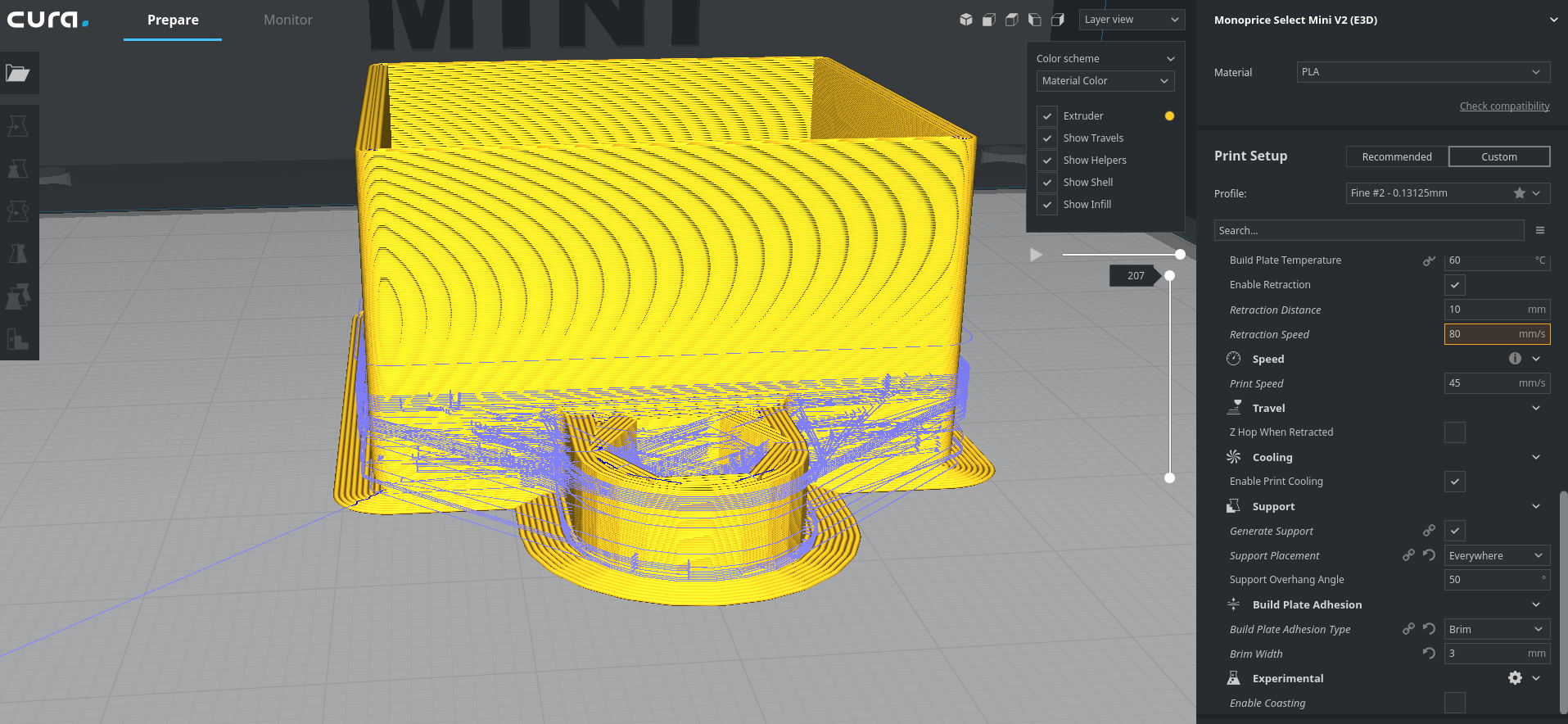

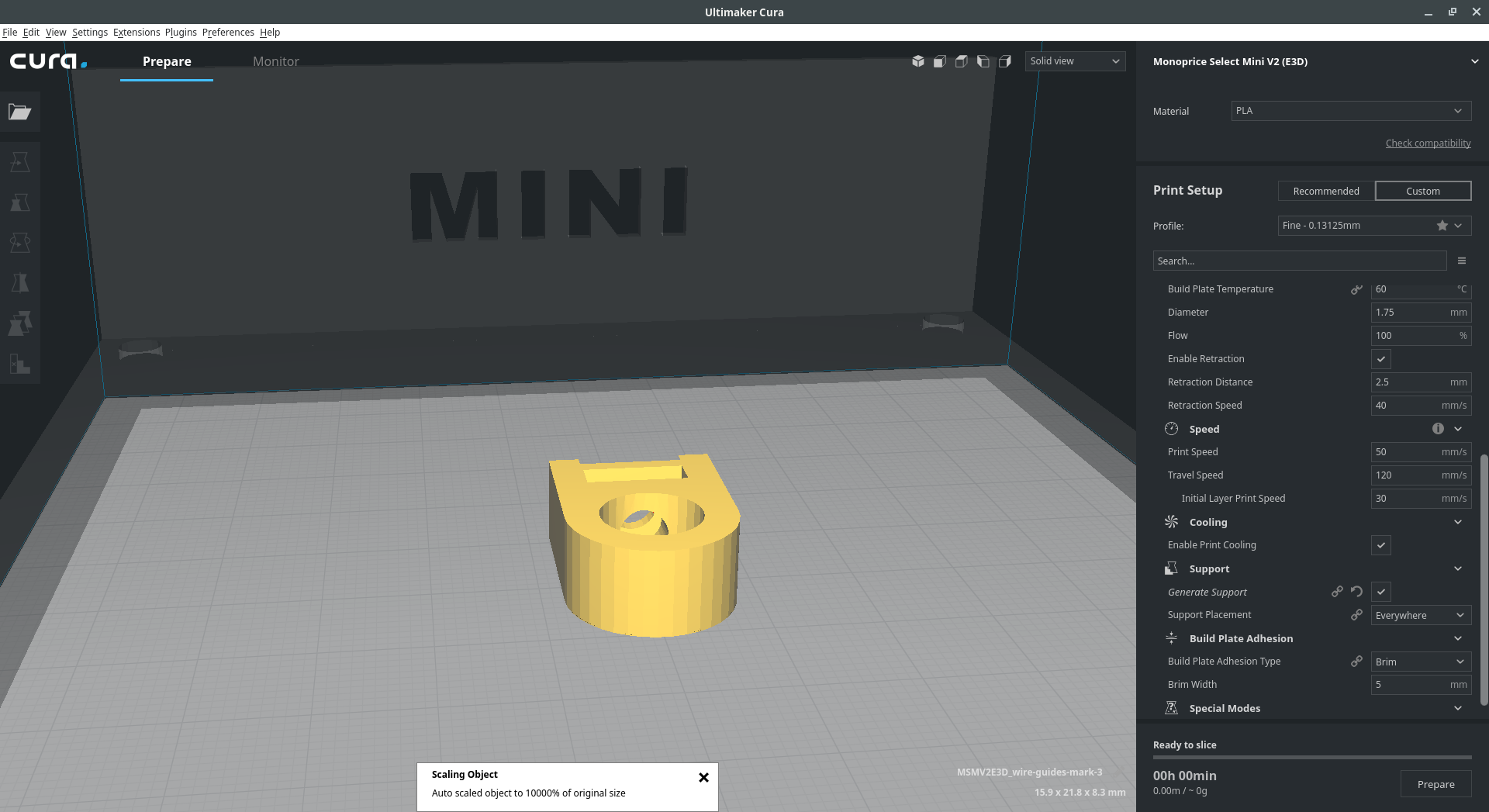

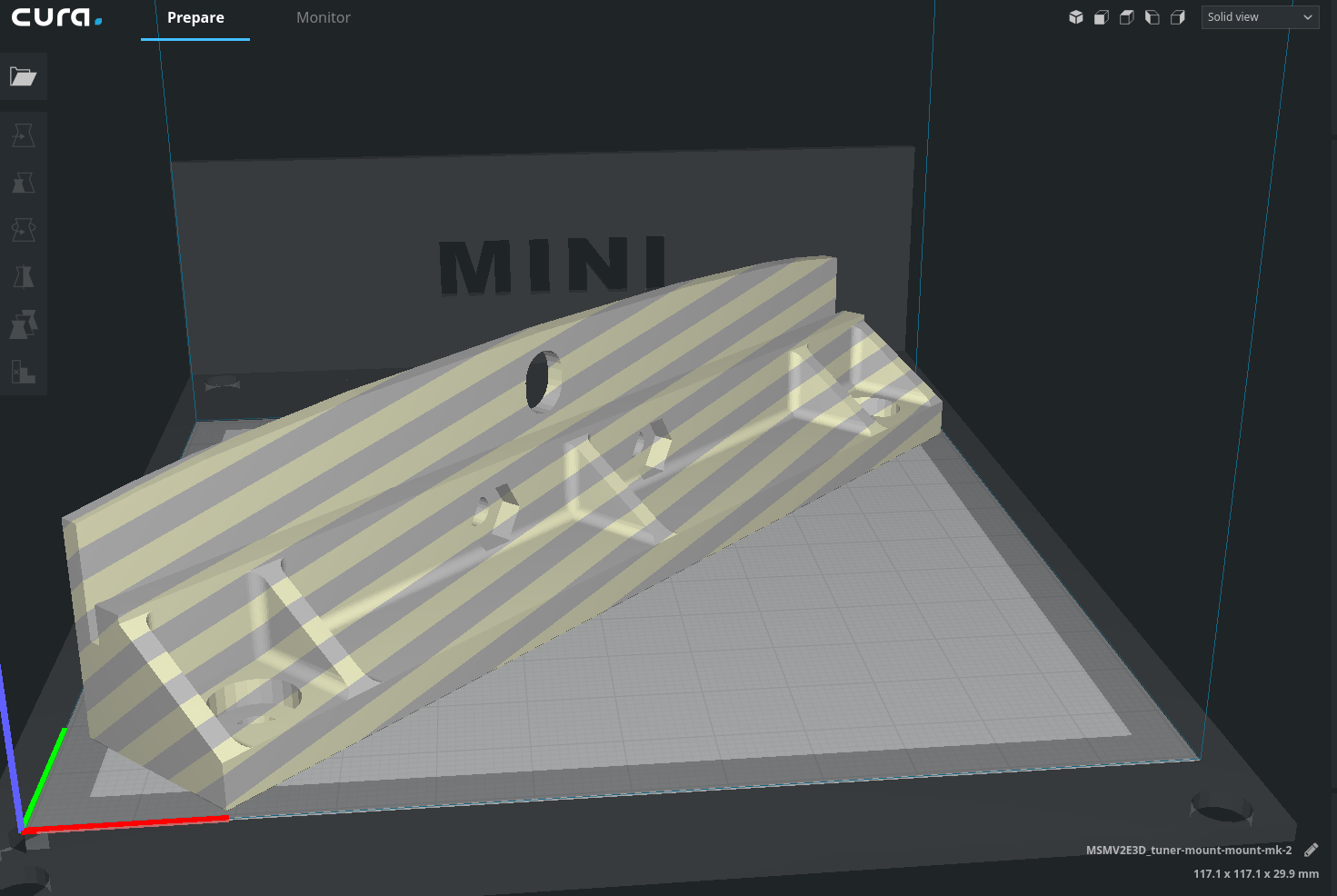

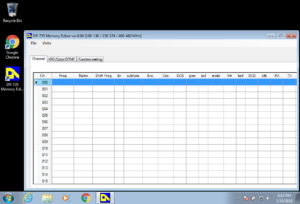

On to other issues: the CPS is windows only. It’s possible to use MM7DBT’s codeplug editor in linux by using wine to run the program. On Fedora 37 I also needed to install winetricks, then use winetricks to install dotnet47. This will install the needed libraries and you can then run the codeplug editor. The installer worked fine, but when attempting to run the codeplug editor I got a weird error about mono libraries. Installing dotnet47 also install mono.

It looks like there’s ways to use serial ports in linux through wine, but a forum post led me to a python script that doesn’t work. It’s definitely not the fault of @davidmpye as Radioddity has likely changed enough of the codeplug format so that it’s no longer compatible with the rt73.

I did find out that I can program on Fedora Linux with the Radioddity CPS. First I needed to add myself to the dialout user group. Then I did the registry addition described here. Then, log out & in.

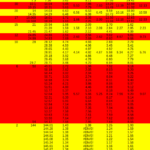

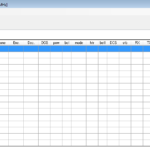

For posterity:

Configure the port–if the device is seen at /dev/ttyUSB0, and you want it to appear to WINE on COM1, edit HKEY_LOCAL_MACHINE\Software\Wine\Ports to have a new string entry named COM1 with value /dev/ttyUSB0

That’s all I have for now.