Yes, I bought a motorcycle. I got bored. Decided I wanted to learn how to ride a motorcycle. Thanks autism!

The Yamaha TW200 is kind of a weird motorcycle today. It’s literally a relic of the past, a platform that hasn’t changed much since it was introduced in 1987. 1988 they changed it from using an AC electrical system to a DC system. Little things changed here and there but it’s mostly been the same. As a side note, if anyone has an 89 they’d like to donate the color scheme is awesome.

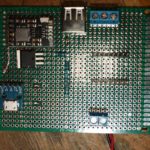

Maybe it was growing up in the 90s, but motorcycles should have a kickstarter. And Yamaha apparently agreed up until the 2001 model year release. What’s interesting is the 20 years later, the parts from a 2000 drop right into the 2020. Pictured below is the parts list for the kickstarter.

And here’s a PDF of all the pictures and things I found on various places online that helped when I installed mine. As a side note, the clutch springs are torqued to I believe 6 ft lbs, which is a really low number. I highly recommend not using a standard torque wrench and instead using a torque screwdriver. Mine is the older, uh, analog version but the point still stands. Snapping a screw in a $366 (tonight, at rocky mountain atv) clutch basket sucks. New tool day always rocks, right?

Not that I recommend using facebook, but if you’re into that kind of masochism then there’s a great little group over there dedicated to the TW200.